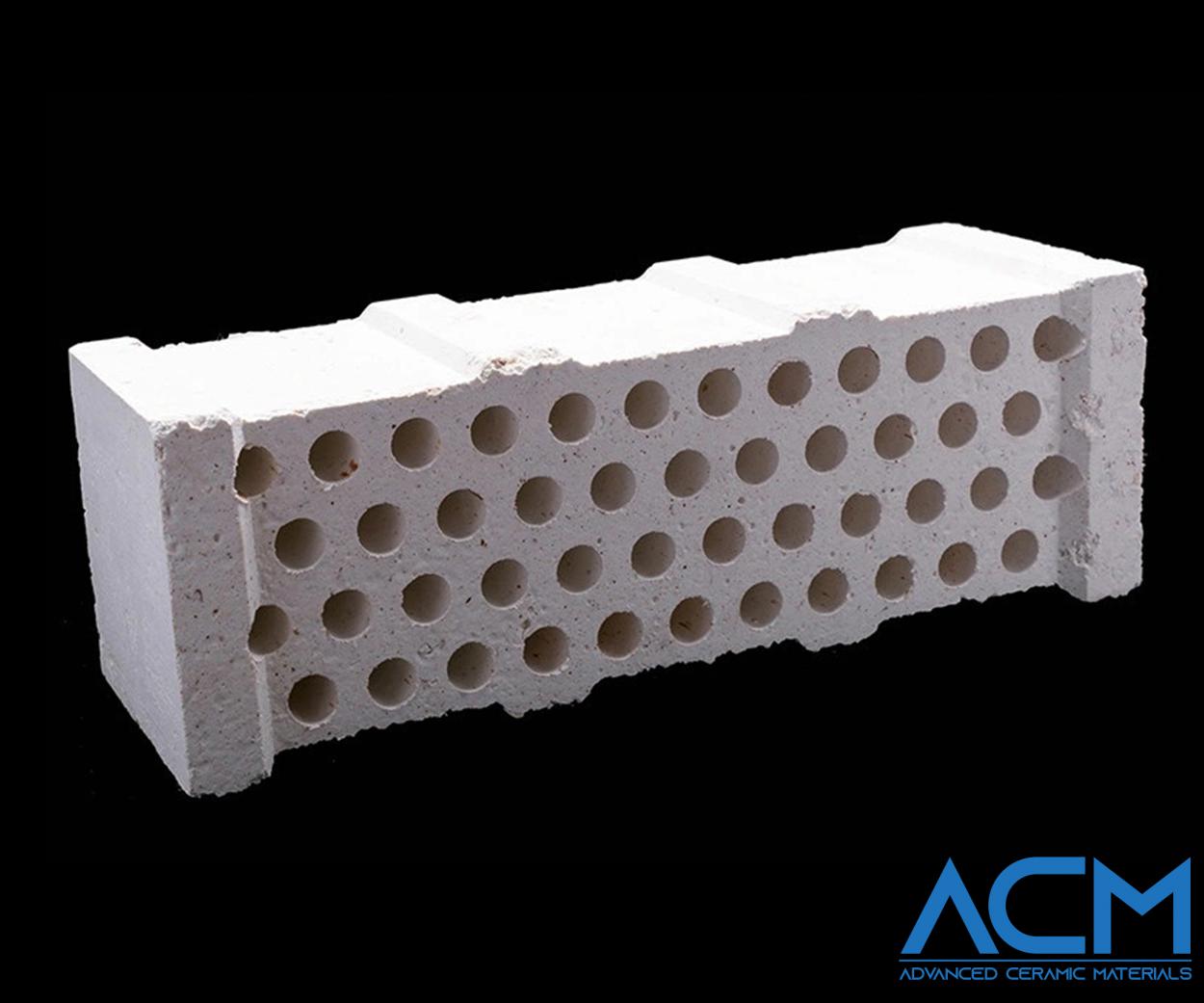

Overview of Silica Refractory Brick

Silica Refractory Bricks are premium refractory materials made predominantly from silica (SiO₂), typically with a silica content exceeding 93%. Recognized for their high melting point and exceptional thermal stability, these bricks are ideal for high-temperature industrial applications. They are particularly suited for environments that demand resilience against acidic slag and prolonged exposure to intense heat, such as glass production, coke ovens, and hot blast stoves.

Silica Refractory Brick Specifications

|

Item |

Specification |

|

|

Type |

Floor & wall bricks |

Other bricks |

|

SiO2 % ≥ |

94.5 |

94.5 |

|

Al2O3 % ≤ |

1.5 |

1.5 |

|

Fe2O3 % ≤ |

1.5 |

1.5 |

|

CaO % ≤ |

2.5 |

2.5 |

|

Refractoriness Under Load ℃ 0.2 Mpa≥ |

1650 |

1650 |

|

Cold Crushing Strength Mpa ≥ |

40 |

35 |

|

Apparent Porosity % ≤ |

22 |

24 |

|

True Density g/cm3 ≤ |

2.33 |

2.34 |

|

Thermal Expansion 1000℃ % ≤ |

1.28 |

1.3 |

|

Residual Quartz % ≤ |

1 |

1 |

|

Permanent Linear Change 1450℃ 2h % |

0–0.2 |

0–0.2 |

Applications of Silica Refractory Bricks

- Glass Furnaces: Commonly used in furnace crowns and other high-temperature areas, these bricks can endure extreme heat and resist acidic slag, making them ideal for glass manufacturing.

- Coke Ovens: Utilized in the walls and roofs of coke ovens for their ability to handle thermal shock and low thermal expansion.

- Hot Blast Stoves: Employed in hot blast stoves within steel plants, where their durability and heat resistance are essential.

Packaging and Handling

Our Silica Refractory Bricks are carefully packaged and handled to maintain their quality and ensure that they arrive in pristine condition.

Frequently Asked Questions (FAQs)

Q1: What is a Silica Refractory Brick?

A Silica Refractory Brick is a heat-resistant brick primarily made of silica (SiO₂), generally with over 93% silica content. These bricks are celebrated for their excellent thermal stability and resistance to acidic conditions, making them ideal for high-temperature industrial uses.

Q2: What are the primary uses of Silica Refractory Bricks?

These bricks are widely applied in glass furnaces, coke ovens, and hot blast stoves, as well as in other high-heat industrial furnaces and kilns where acidic exposure is prevalent.

Q3: What advantages do Silica Refractory Bricks provide?

Silica Refractory Bricks offer exceptional thermal stability, resistance to high temperatures, low thermal expansion, and strong protection against acidic slags, ensuring durability in extreme industrial environments.