SM6077 Ceramic Blasting Media

Ceramic Blasting Media Overview

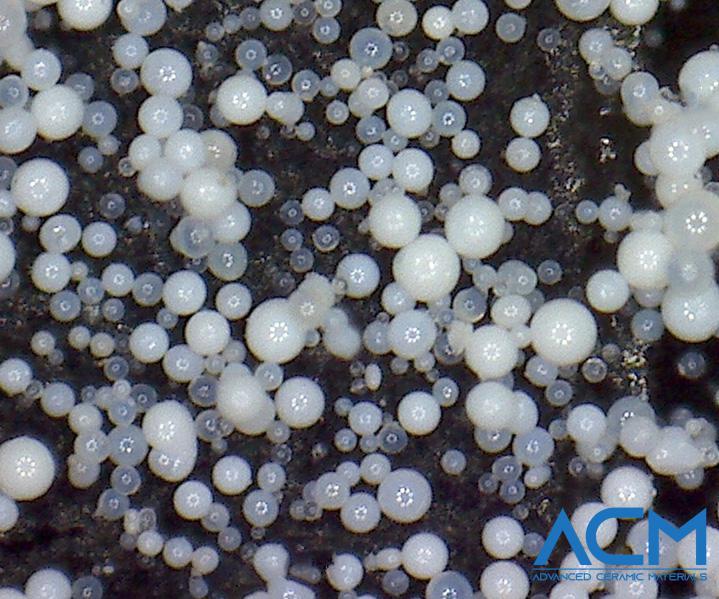

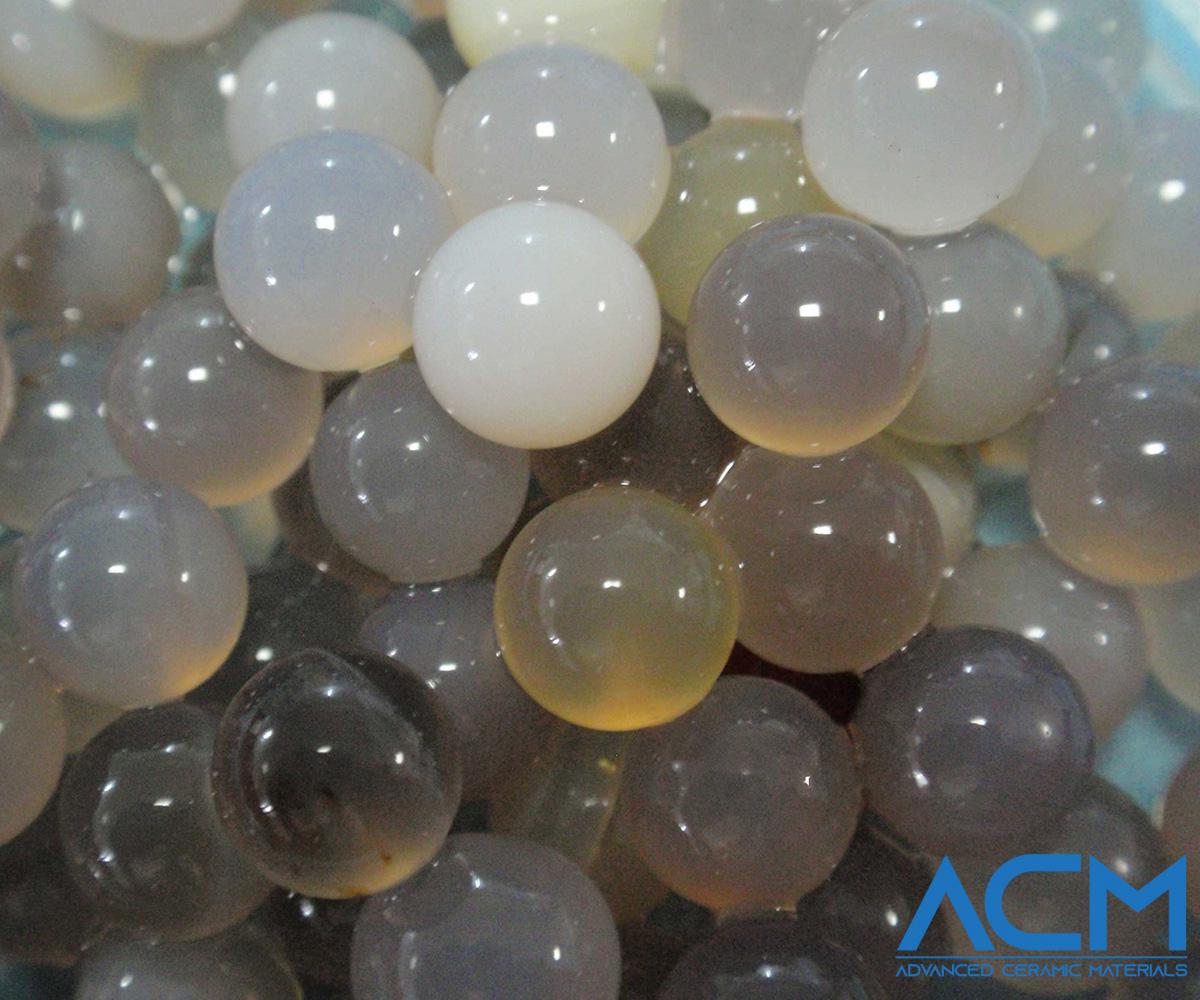

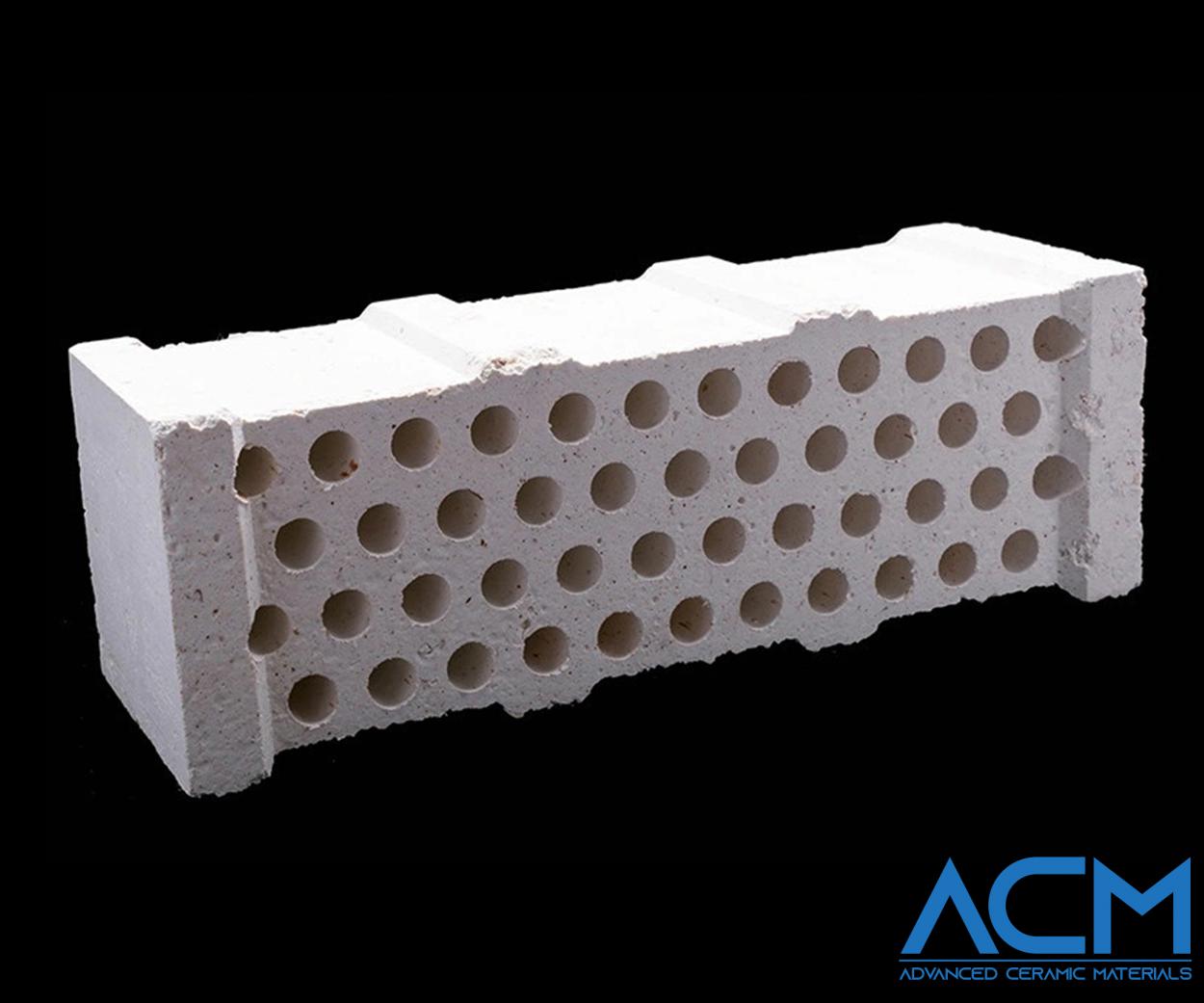

Ceramic Blasting Media are created using a specialized electric fusion forming process, resulting in high density, excellent sphericity, and superior fracture toughness. Compared to traditional materials such as glass beads, corundum, and steel shot, ceramic blasting media offer benefits including reduced contamination, increased efficiency, enhanced consistency, and extended service life.

Ceramic Blasting Media Specification

|

Specific Gravity |

3.8kg/dm3 |

|

Bulk Density |

≥2.3kg/L |

|

Vickers hardness |

>700kg/mm2 |

|

Elastic Modulus |

>330Gpa |

|

Minimum Order Quantity (MOQ) |

25kg/drum |

Chemical Composition

|

Chemical Composition |

ZrO2 |

SiO2 |

Al2O3 |

|

Wt% |

60-70 |

28-33 |

<10 |

Specification

|

Model |

Diameter (φ) mm |

|

NB205 |

0.0-0.063 |

|

NB170 |

0.045-0.090 |

|

NB120 |

0.063-0.125 |

|

NB100 |

0.125-0.180 |

|

NB80 |

0.180-0.250 |

|

NB60 |

0.125-0.250 |

|

NB40 |

0.250-0.425 |

|

NB30 |

0.425-0.600 |

|

NB20 |

0.600-0.850 |

*Sizes can be tailored to meet specific customer requirements.

Ceramic Blasting Media Applications

- Grinding Media: Ideal for processing pigments, dyes, paints, inks, varnishes, pesticides, and pharmaceuticals.

- Filtration Media: Used as filtration media, catalyst carriers, and for polishing and cleaning.

- Sealing Components: Suitable for high-precision sealing components.

Ceramic Blasting Media Packing

Packaged in 25 kg drums, available in composite woven bags or drums.

-

Attachment (Optional)

No file chosen