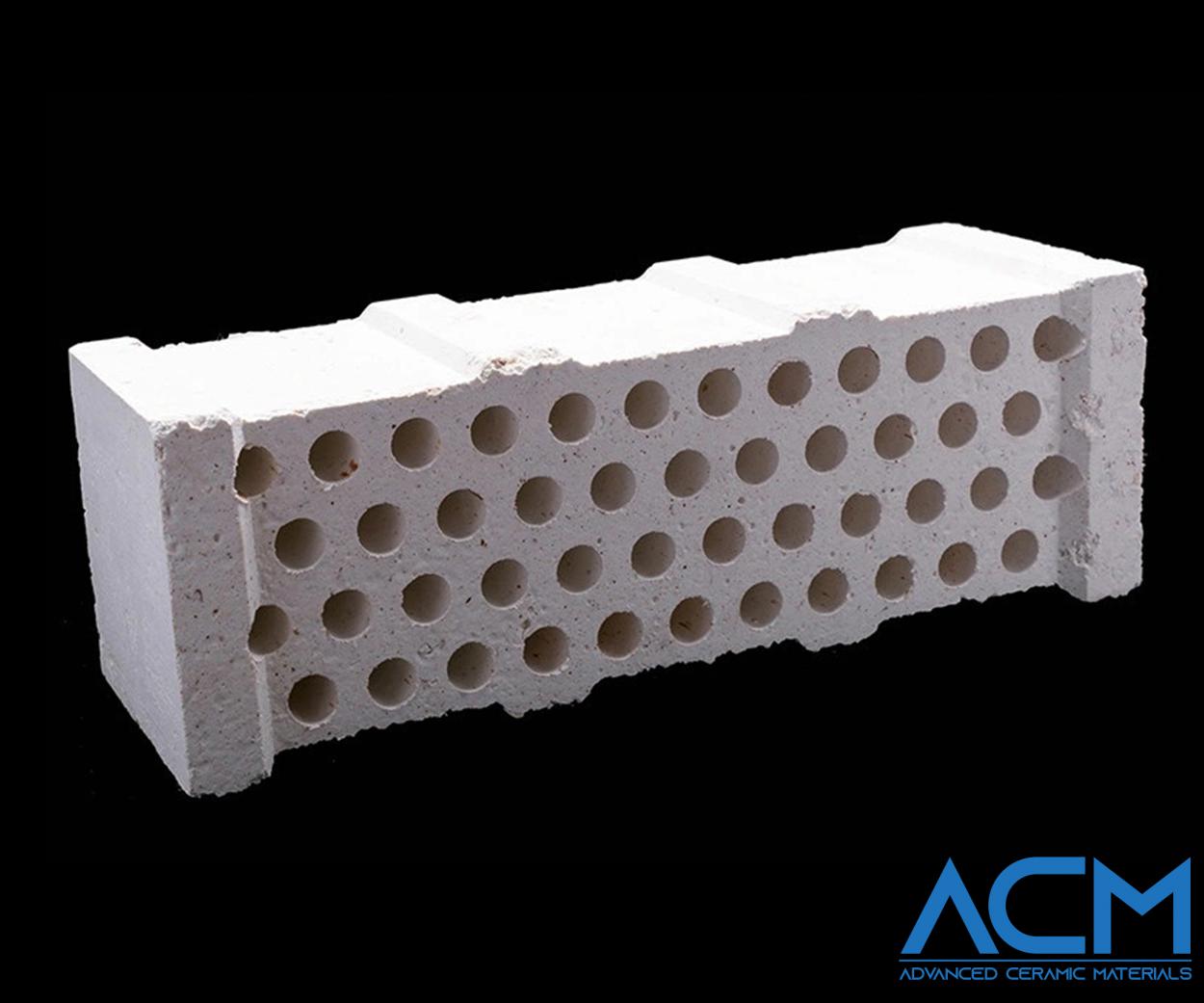

SM6134 Silica Checker Brick

- Catalog No. SM6134

- Material Si2O3

- Apparent Density 2.32 g/cm3

- Content Si2O3: 95%

- Max Working Temp. 1650 ℃

SM6134 Silica Checker Brick

Silica Checker Brick Overview

Silica Checker Brick is a high-quality refractory brick made primarily from silica (SiO₂). It is specifically designed for use in regenerative furnaces such as coke ovens, hot blast stoves, and glass furnaces. The unique checker-like structure of these bricks maximizes surface area for heat exchange, enhancing the thermal efficiency of furnaces by improving heat storage and recovery.

Silica Checker Brick Specifications

|

Item |

Specification |

|

SiO2 % ≥ |

95 |

|

Al2O3 % ≤ |

1.0 |

|

Fe2O3 % ≤ |

1.3 |

|

Cold crushing strength Mpa ≥ |

35 |

|

Apparent porosity % ≤ |

24 |

|

Creep rate 0.2MPa 1500℃ 50h % ≤ |

0.8 |

|

Apparent density g/cm3 ≤ |

2.32 |

|

Thermal expansion 1000℃ % ≤ |

1.25 |

|

Residual quartz % ≤ |

1.0 |

|

Refractoriness under load T0.6 ℃ ≥ |

1650 |

Silica Checker Brick Applications

- Hot Blast Stoves: Used as a regenerator to preheat the air blast for blast furnaces in steelmaking. The checker brick alternates between heating and cooling phases to efficiently store and release heat.

- Coke Ovens: Applied in the regenerative chambers to recover heat from exhaust gases, enhancing energy efficiency.

- Glass Furnaces: Utilized in the regenerator sections to improve the efficiency of glass melting operations through effective heat recovery.

- Other Industrial Furnaces: Employed in various furnaces where heat recovery is crucial, such as in non-ferrous metal production and ceramic kilns.

Silica Checker Brick Packaging

Our Silica Checker Brick is carefully packaged to ensure it arrives in optimal condition. We use robust packaging materials and methods to protect the bricks from damage during storage and transportation.

FAQs

Q1: What is Silica Checker Brick?

Silica Checker Brick is a type of lightweight refractory brick made primarily from silica (SiO₂). It is designed for high-temperature applications in regenerative furnaces where efficient heat storage and recovery are essential.

Q2: What are the main benefits of using Silica Checker Brick?

Silica Checker Brick offers several benefits including high thermal efficiency, excellent heat storage and recovery capabilities, and good resistance to thermal shock. Its unique checker-like structure enhances surface area for better heat exchange.

Q3: In which industries is Silica Checker Brick typically used?

Silica Checker Brick is commonly used in industries such as steelmaking (hot blast stoves), glass manufacturing, and other high-temperature industrial processes where heat recovery and efficient thermal management are crucial.

Q4: How should Silica Checker Brick be handled and stored?

Silica Checker Brick should be handled with care to avoid damage. It should be stored in a dry, clean environment to prevent contamination and ensure its longevity. Proper packaging is used to protect the bricks during transportation.

Q5: Can Silica Checker Brick be used in all types of furnaces?

Silica Checker Brick is particularly effective in regenerative furnaces such as coke ovens and glass furnaces. It may not be suitable for all furnace types, so it's important to consult with a specialist to ensure it's the right choice for your specific application.

-

Attachment (Optional)

No file chosen